Mechanical Engineering PPE

PPE Requirements for Mechanical Engineers, Electrical Engineers, and Civil Engineers in Australia

PPE for Engineering is vital in Australia’s crucial industry sectors where hard-working engineers design, maintain, and fix infrastructure, driving societal productivity. Expert engineers are innovating new ideas and solutions every day across Australia, from the medical sector to the mining and agriculture industries. The number of qualified engineers in Australia will likely double by 2030 to meet our growing nation’s high infrastructure demands.

Engineers work in a wide variety of workplace settings, including, but not limited to, laboratories, design offices, construction sites, mine sites, shipyards, research stations, and agricultural properties. Because engineers may need to complete work or check progress in multiple locations during the day, travel can also take up portions of their workday.

When examining the requirements for PPE for engineering in Australia, it is important to note that many engineers use specialised tools and protective equipment depending on their industry and workplace settings. With this in mind, we have compiled a list of the top 5 PPE for engineering products most essential to Engineers in Australia.

Best Class 5 Ear Protection for High Noise Environment Engineers

All workers in high-noise environments are at risk of hearing damage and injury, including engineers. From monitoring operations in a control room to visiting a project construction site, many engineers must work in high-noise areas. The Engineering Industry is often involved in finding solutions to reduce noise exposure for workers across many sectors. However, when noise is unavoidable, PPE offers a last line of defence against hearing damage.

Ear protection for engineers must be comfortable, high-quality, and easily visible. Over-ear protection is often the most convenient form of hearing PPE for engineering. Earmuffs can be worn comfortably, placed securely over hard hats, and removed easily when moving back and forth between different noise level areas.

Our VISION Safe Earmuff suits medium to high noise environments and provides the best Class 5 protection. Featuring ultra-soft padding on the cups and headband, the VISIONSafe Earmuff offers premium comfort when being worn and at rest, and the high-vis green allows for easy spotting.

Most Popular Safety Glasses for Mechanical Engineering PPE in Australia

Eye protection is crucial for engineers spending time in high-risk environments such as construction sites, power generation stations, or even laboratories. Hazards in these environments can include chemical splashes or spills, fumes, arcing or sparks, shards, and other particles. Protective eyewear can help to keep workers’ eyes safe when working around these risks.

Engineers have many options regarding safety glasses, goggles, and masks, and the appropriate eye protection always depends on the exact job and risks. For many applications, lightweight medium-impact rated safety glasses will offer good protection. However, positive-seal safety glasses that use a foam layer to seal onto the face can provide even better comfort and benefits, such as blocking sweat, smoke, and other fumes from getting to the eye area.

Our Gasket 135 Positive Seal Safety Glasses feature interchangeable temple ends and head straps for a secure fit around the face and head. The positive seal foam insert can be detached as required, and the lenses are anti-fog, anti-scratch treated to maintain superior visibility.

The Best Hard Hat Accessories for Sun Protection are the Gobi Over Hat and the Attach-A-Flap

Engineers in Australia may work indoors and outdoors depending on their job role and the industry sector. Sun safety is paramount when engineering involves outdoor work, such as site surveying, construction, agricultural work, or many mining roles.

Outdoor workers in Australia are at a higher risk of developing skin cancer due to UV radiation exposure. Using sun-protective clothing is an ideal way to help protect outdoor workers from dangerous UV radiation and can be used in conjunction with existing PPE for engineering, such as hard hats. Hard hat attachments for engineers are often an excellent solution for sun safety.

Sun-protective hard hat accessories provide comfortable shade and should not hinder the wearer’s sight or get in the way of completing work safely. UVeto Australia takes sun protection seriously and has designed many popular hard hat attachments for outdoor workers, such as the Gobi Over Hat, Brim’ N Shade and the Attach-A-Flap. These hard hat accessories are UPF50+ rated, provide excellent shade and comfort, and are ideal for engineers working outdoors.

Sun-protective hard hat accessories provide comfortable shade and should not hinder the wearer’s sight or get in the way of completing work safely. UVeto Australia takes sun protection seriously and has designed many popular hard hat attachments for outdoor workers, such as the Brim’ N Shade and the Attach-A-Flap. These hard hat accessories are UPF50+ rated, provide excellent shade and comfort, and are ideal for engineers working outdoors.

Prevent Dry Skin at Work with Derma Guard Hand Cream

With the wide variety of work engineers in Australia do, keeping hands clean and safe helps to maintain productivity and comfort. Whether in the office completing system design plans, surveying out in the sun, testing a new solution in the lab, or heading out to site to troubleshoot problems – engineers are continually using their hands at work.

The best everyday PPE for engineering for hands is Derma Guard Cream. One application provides 4 hours of protection against oils, fuels, solvents, resins, glues, bacteria, irritants, and emergency protection against acids and bases. Derma Guard also moisturises and nourishes the skin to ward off cracks and splits and help manage conditions like eczema. The formula is ideal for engineers as it is non-toxic, non-greasy, and can be used with gloves.

Mechanical Engineering PPE First Aid Kit for Worksites, Vehicles and Field

Emergency preparedness is vital for all industries, so appropriately sized first aid kits should be in every workspace. But what happens when people need to travel to meet clients or travel between worksites, as engineers often do? Portable personal emergency kits are the solution.

The Essentials First Aid Kit, designed by First Aid Works, is the best portable emergency kit to keep in the car, office, or work bag. It contains everything needed to treat minor wounds, perform safe CPR, and stabilise injuries till professional treatment can be provided. First Aid Works has packed all the essentials into a compact nylon case, making the Essentials First Aid Kit easy to store and find when an incident happens.

Workplace Safety Tips for Mechanical Engineers

Tips designed to reduce the risk of injury at the workplace and have a safe, productive environment ready to thrive.

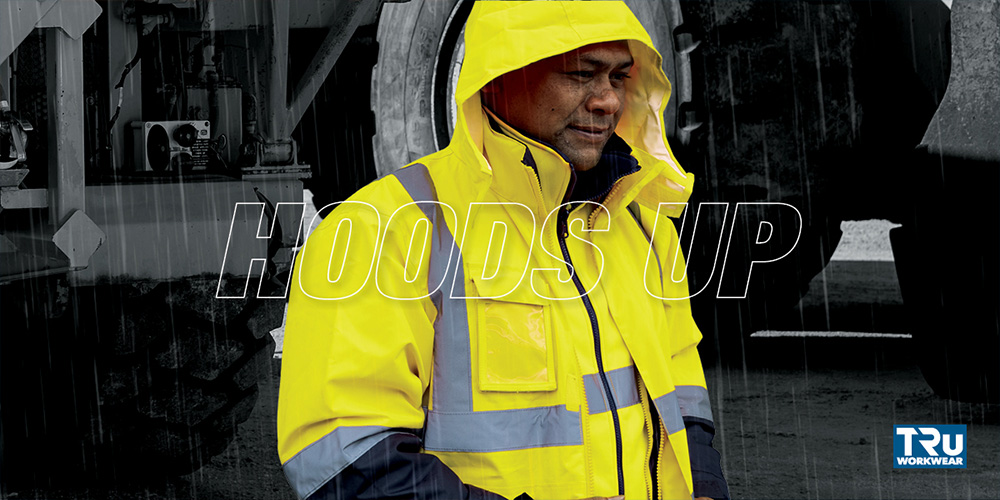

Personal protection equipment (PPE) is a must for mechanical engineers. Image courtesy of All Seasons Uniforms

In the U.S., the market for mechanical engineering was worth around $421 billion in 2020. It’s clearly a field that has remained very much in demand for decades now. After all, being a mechanical engineer comes with a vast set of benefits.

However, the industry itself is also quite dangerous. Quite a few things can go wrong at the workplace. That’s why it’s crucial to keep the industry as safe and risk-free as possible. Luckily, there are various methods of doing just that, and if you need some help regarding workplace safety as a mechanical engineer, you’ve come to the right place.

This article provides a list of handy safety tips for mechanical engineers. By adhering to these tips, you will reduce the risk of injury at the workplace and have a safe, productive environment ready to thrive.

Familiarizing with OSHA Standards

For those of you not familiar with this term, OSHA is an acronym that stands for Occupational Safety and Health Administration. OSHA is a large regulatory agency of the U.S. Department of Labor, whose job is to help reduce workplace injuries, accidents, and fatalities. The organization does that by enforcing specific workplace standards and inspecting companies to check if the CEOs adhere to said standards to the letter.

Both as a worker and a business owner, you will want to familiarize yourself with OSHA standards for mechanical engineering. There are two major reasons for doing that. The first relates to your own safety. By learning what the regulations for your workstation are, you can perform your task safely and by the books.

The second major reason for learning OSHA standards is to keep the company accountable. As a business owner, you want to be in good graces with OSHA, or else you might be struck with a penalty. But, more importantly, as a worker, you can spot safety violations and report them to an official body. OSHA also offers whistleblower provisions and an up-to-date protection program that ensures worker safety in cases of reporting violations.

Safety Training

Mechanical Engineering PPE Safety training is a crucial part of any industry, with mechanical engineering being no exception. And while a lot of workers find safety drills and training dull, we can’t emphasize how dangerous it is not to attend them.

By going over the learning program, you will acquire a set of skills necessary for progressing safely with your work. Those include issue reporting, operational practices during an emergency, what numbers to call and experts to talk to if something happens, etc.

One area where mechanical engineers require safety training involves hazardous chemicals. Generally speaking, engineers don’t work with chemicals as often as professionals from other industries might, but they are still required to go through some of the basics. Training to handle dangerous substances usually involves proper protection from exposure, reading material safety data sheets, and knowing how best to react if exposure to these chemicals does occur.

PPE

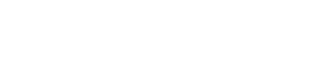

Mechanical Engineering PPE Personal protection equipment is a must in any industry as hazardous as mechanical engineering. According to various OSHA standards, a typical mechanical engineer will need to wear different types of gear depending on their workstation and the level of exposure to danger.

One key element of Mechanical Engineering PPE involves high-visibility clothing. An engineer might be out in the field taking care of the machinery. Hi-vis clothing can help both during the day and at nighttime. As you work during the day, passers-by can easily spot your fluorescent vest or overalls, so if an accident occurs, you can expect help to be on the way soon. During the night, the material of hi-vis clothing reflects light, once again making it easier for someone to spot you.

Naturally, hi-vis clothing is merely one of many gears that a mechanical engineer will require to wear. Depending on what section of the facility they’re in, engineers will require different types of safety eyewear. These can be either glasses, goggles, or face shields. Furthermore, they can either protect your eyes from lasers, chemical splashes, fine particles and small debris, or sudden impact.

Some other types of PPE for mechanical engineers include:

- Hard helmets;

- Steel-toed boots;

- Earplugs;

- Gloves; and

- Respiratory protective equipment (RPE).

Cleanliness

In the broadest terms possible, cleanliness is pretty much self-explanatory. It generally refers to keeping the workstation, the tools, and the machinery as clean and operable as possible. Workers ought to clear out any debris and clutter that presents an obvious obstacle. Furthermore, if there are any spills, the cleaners should mop them up at once. Leaving any liquid untended can result in dangerous fumes. Hoses, cables, and other important items need to be kept in a safe spot away from the workers so that they don’t accidentally snap them doing their everyday work or trip on them.

Of course, workers also need to keep themselves clean. Lack of personal hygiene can result in various diseases and infections spreading all over the workplace. That can severely harm your coworkers and have a serious impact on productivity.

Safety Signs and Key Safe Locations

In Mechanical Engineering PPE Not a lot of workers can read safety signs, and that’s a major problem. After all, if you don’t know what a particular sign is warning you of, you can enter a dangerous area without wearing the proper equipment. The best way to tackle this problem is to go over the facility and familiarize yourself with all of the signs. In addition, take notes of where each individual sign is. That way, you’ll know where to find them and how to prepare yourself before entering that area.

And speaking of different areas in your workplace, there are several key safe spots you will need to consider. Those include first aid stations, emergency exits, and all of the spots with fire extinguishers. Learn where all of these places are so you can be prepared in case of an emergency.

Mechanical Engineering and Workplace Safety Summarized

The safety tips in this article will come in handy for any mechanical engineer or CEO. However, they are not limited to this industry alone. If you happen to be employed in a different field, you’ll still want to learn everything you can about safety and the potential dangers of your workstation. Remember, a safe working environment is one that will attract future employees. So, for all of those potential mechanical engineers out there, take these safety tips under serious consideration.

to ensure safety in various work environments. Here’s an overview of the services we offer:1.ppe protection 2.body protection 3.respiratory protection 3.fall protection 4.foot protection 5.hand protection 6.hearing protection 7.eye and face protection 8.heat protection 9.gas protection 10.head protection 11.chemical protection and 12.lock out and tag out protection

“Our commitment to quality and reliability makes us the brand you can rely on.”

“Stay ahead with our expertly designed new styles.”

“Our commitment to excellence ensures the quality you deserve.”

“Twipake Limited streamlines your wardrobe needs for a hassle-free experience.”

“Twipake Limited stitches together fashion and safety seamlessly.”

“Twipake Limited ensures timely availability of safety essentials.

- Beautiful Map and easy to locate shop

- Supply of Equipment

- Present your services with flexible

- Twipake Limited is committed to excellence.

- We streamline workwear wardrobe needs.

Certainly! Twipake Limited is dedicated to providing top-quality Personal Protective Equipment (PPE) as our core service. Here’s how we ensure safety and reliability:

1.Supply of Safety Equipment:We specialize in supplying essential safety gear, including:Safety Helmets , Safety Uniforms, Safety Boots and Other Safety Items(From gloves to eyewear, we cover all safety essentials_

2.Expertise and Trust 3.Efficient Wardrobe Management 4.Stylish Stitches and New Designs 5.Quality Assurance:

Twipake Limited, we prioritize safety and convenience for our customers. Our core service includes efficient delivery of Mechanical Engineering PPE Personal Protective Equipment. Here’s how we ensure a seamless experience:

1.Timely Delivery 2.Customized Solutions 3.Safety Gear at Your Doorstep 4.Compliance and Reliability 5.Customer Satisfaction:

-

- Your satisfaction matters to us. We strive to exceed your expectations with hassle-free delivery services.

- Focus on our core business while we handle the logistics.

However! At Twipake Limited, we take pride in providing comprehensive support for Personal Protective Equipment (PPE). Here’s how we ensure a seamless experience for our customers:1.Mechanical Engineering PPE Sales and Delivery 2.Warranty and Replacement 3.Customer Satisfaction:

-

- Your safety and satisfaction are our priorities.

- Contact our support team for any PPE-related inquiries or assistance.

For all your safety needs, trust Twipake Limited – your partner in protection!

During this phase, we identify the specific PPE requirements based on the customer’s industry, workplace hazards, and employee roles.

These templates outline the recommended safety gear, quantities, and associated costs.

We arrange for shipping and delivery of the PPE directly to the specified address.

Our goal is to provide timely and efficient service, ensuring that the customer receives the necessary safety gear promptly.

TWIPAKE LIMITED is the leading distributors, Agent and supplier of quality TRu safety products, Force360 and Bata Industries in Tanzania and All East Africa (EA) Countries Tanzania, Kenya, Uganda, Rwanda, Zambia, Zimbabwe, Mozambique, Zimbabwe, Congo and Burundi.

You can Visit Us for More Details of Mechanical Engineering PPE

Home | About Us | Our services |Our brands | Store locator | Contact Us | News

For More Information about Twipake Limited

Terms and conditions | Privacy policy | Size guide | Help and support | Shipping and delivery | Returns and refunds | FAQs

We deal with All Kind of PPE Protection you can see or services on the Below

Body Protection | Respiratory Protection | Fall Protection | Foot Protection | Hand Protection | Hearing Protection | Eye And Face Protection | Heat Protection | Gas Protection | Head Protection | Chemical Protection | Lock Out And Tag Out Protection | PPE Tools And Accessories

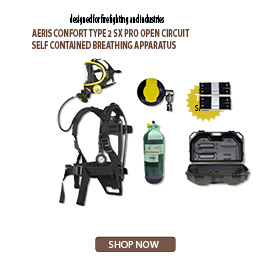

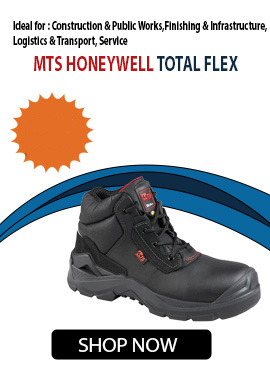

Our Products are from Leading International Mechanical Engineering PPE Brands We are Main Agent of Tru , Force360 and Bata Industries In Tanzania and East Africa

Tru | Bata Industries | Force360 | Honeywell | Optrel | Regeltex | BBF | Nikki | Bova | Vaultex | CAT | 3M Safety | Deltaplus | Checkpoint Martins | Vehicle Safety Flags | Granite Workwear | Drager Graeger | Wilhelmsen | Jonsson | Alcohol Breathalysers | MTS | Red Wings | Workland Safety | MSA

Further More In PPE tools and Safety Gear We have Customers from different categories and the different category of Safety PPE Tools used

Safety Tools PPE | Industrial Safety PPE | Contractor Safety PPE | Mining Safety PPE |ICT Networking And Telecom Engineering PPE | Oil And Gas PPE | Security and Guard PPE | Electrical Engineering PPE | Civil and Construction Engineering PPE | Shipping, Marine and Fishing Engineering PPE | Explorations And Survey Engineering PPE | Mechanical Engineering PPE | Hospitality & Hotel Safety PPE | Tour Guide Safety PPE | Clinical, Health & Hospital Safety PPE | Personal Protective Equipment (PPE) | Safety Gear PPE

Twipake is The Leading Suppliers of Personal Protective Equipment, Our PPE Main Categories are

PPE | FOOTWEAR |WORKWEAR | MEN |WOMEN | FASHION

In Mechanical Engineering PPE’s Are International Recognized Brands

Tru | Bata Industries | Force360 | Honeywell | Optrel | Regeltex | BBF | Nikki | Bova | Vaultex | CAT | 3M Safety | Deltaplus | Checkpoint Martins | Vehicle Safety Flags | Granite Workwear | Drager Graeger | Wilhelmsen | Jonsson | Alcohol Breathalysers | MTS | Red Wings | Workland Safety | MSA

Let’s delve into the essence of our premium brand, Twipake Limited, and explore how we stand out in the realm of Personal Protective Equipment (PPE): We conductedresearch in 2019

Our goal was clear: to provide cutting-edge Mechanical Engineering PPE – Personal Protective Equipment that surpassed industry standards.

The research phase involved studying materials, testing durability, and analyzing ergonomic designs. We explored innovations in respiratory protection, fall prevention, and chemical-resistant gear. Armed with knowledge, we were ready to revolutionize the safety landscape.

- Essy and Understandable Top Brand Simplified Safety Solutions

- Flexibilities Tailored Solutions for Diverse Needs

- More Creativities in PPE Innovating Safety

- 5. Adjustment Possibilities for Wrong Size PPE Ensuring Perfect Fit

- We are 100% focused in our customers Needs and available Top PPE Brand